|

|

|

Begin OCR Text:

either increase or reduce the number of sh_ims

equaIIy fo_ both bolts. More positive camber is

obtained by removing shims and negative camber

by _ncreas_ng the number of shims.

The shim thickness required to alter the angIe

to a ce__tain e_tent is shown in the diagram in fig.

_-9. Shims are stocked in thicknesses of O.15-O5

-1._3.O and 6.O mm (O.OO_O.O2O-O.O3_O.12O

and O 24O''). The total thickness of shims at each

bolt may not e_ceed 12 mm (O.48''). The difference

in thickness between the shims at the front and

rear bolts may be ma_. 2.5 mm (O.1''). Note that j v,,o,L,v,o,

an eqUal nUmber of Shims muSt be removed or F_g. 6-__. Adj_,,__,,g ,__..,,,. _,,. ,,___,_ _,,_

added at both the bolts if the camber is not to be 1 Ad_us__ng screw

altered.

After adjust_ng tighten the bolts to a torque of 5.5-

7 O kpm (4O-5O Ib.ft.) and lock them.

In order to save time and labour adjust the caster

and šamber at the same t_me by remov_ng or add- ADlUSTING TOE_lN

_ng shims for the camber and altering the number The toe-in should be O4 mm (O-O.16''). Incor-

of shims for the caster. for e_ample, if the camber rect toe-in is adjusted by slackening the locknuts

_s increased O.6' and the caster 1/4', first remove on the tie rod, after which the rod is turned in the

2.5 mm (O.1'') in shims at both the bolts and move required d_rect_on. The d_stance between the tyres

O.15 mm (O.OO6'') in shim thickness from the front at the front is reduced, that is to say, toe-in _s

to the rear bolt. increased by turning the tie_rod in the normal

direction of rotation of the wheels. __ighten the

Iocknut after adjustment to a torQue of 7.f9.O

kpm (55-65 Ib.ft.).

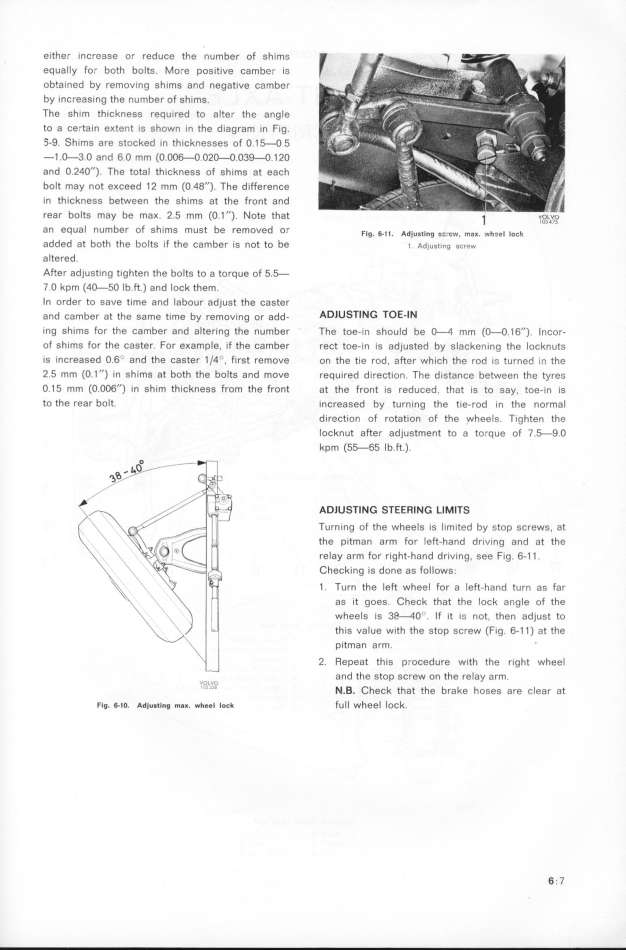

ADlUSTING STEERING LIMITS

Turning of the wheels is lim_ted by stop screws, at

the pitman arm for left_hand dr_ving and at fhe

reIay arm for right-hand driving, see fig. 6-11.

Checking is done as follows_.

1. Turn the Ieft wheel for a left_hand turn as far

as it goes. Check that the lock angle of the

wheels is 3P_4O'. If it i__ not, then adjust to

this value with the stop screw (Fig. ti11) at the

pitman arm.

2. Repeat this procedure with the r_ght wheel

,o, u and the stop screw on the relay arm.

' _'_' N.B. Chešk that fhe brake hoses are clear at

Fig. 8_o. Adju__ing m8_. __ee_ ioc_ full wheel lock. 6.7

|