|

|

|

Begin OCR Text:

l NSTALLING

j _ g 1 1 1 O 1 5 _ th b k _ EUR th b k h ee

çrew e ra e va ve on O e ra e OSe, S

f_g 5-58 Place the valve _n posit_on and CheCk

thae there _s no tens_on in the hose f_t the attach-

_ng bolts and connect up the brake pipe T_ghten

the connections BIeed the brake system

'' .

ADlUSTl NG

The adjusting screw (1 2. F_g 5_41 ) is not intended

for adjusting in the normal mean _ng of the

word

_fg funçf_on _g to balançe the variations in the manu-

z o g z j j g jz j j factur_ng. The carefully checked adjustment made

'i_'i_'_ at the qnqtial assembl _ng _s generally sufficient for

F_g __sa Bra_e valve d_smantled the entire __fetime of the valve For thiS feaGon_ the

_ P_ug 14 S_,ing hoUSlng adjug_ing g_few _ugf no_ be fou_hed.

2 O.,i_g l5 Refainer d h b b_ h d th

g p_,,,,, ,,,_ _g o ,,,g _f, afier recon itioning, _t as een esta _s e w_

9 Bracket 2O HoUSing the he_p of tegt_ng aççord _ng to _ Fau _f Traçing'',

l O Sp,ing 2l P_Ston h g _ 5o h h t

i i _,_,_,,, 22 vaIve hous_ng paragrap . roup . t at t e oU golng PreS SUre

_ies outsqde the Iqmit val ues. an ad)ustment Can be

made w_th the adjust_ng screw Turning the screw

cloçkwise increases the outgoing pressure Lock

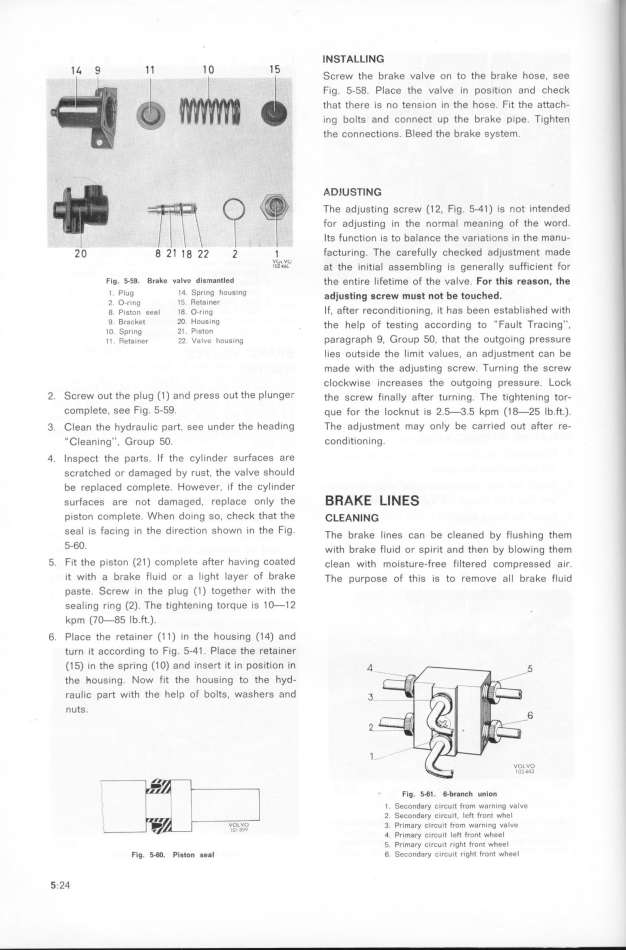

2 _crew out the pl ug (1 ) and press out the pl Un9er the screw f_nal Iy after turning The tightening tor-

complete, see Fig 5-59 que for the locknut is 2 f3 5 kpm (1 _25 Ib ft )

3 __ean fhe hydrau_ _ç parf gee under EURhe head_ng The adjustment may only be Carr_ed out aftef re-

_ __ean_ng'', _roup 5O cond_t_ On Ing

4 lnspect the parts If the cyl _nder surfaceS are

gçratçhed or damaged by rust, the valve should

be reptaced complete However. _f the cyl inder

surfaces are not damaged. replace only the B RAKE Ll _ ES

p_gton complete When do_ng so, check that the _LEANl NG

gea_ _s faç_ng in the direction shown _n the Fig Th b k _ b _ d b F_ h g ehem

e fa e IneS Can e C eane y US In

5-6O_ w_th brake flu_d or sp_riEUR and then by bIow_ng them

5 F_t the piston (2t ) complete after having coated ç_ean wqth moisture-free filtered compressed air ;

qt w_th a brake flu_d or a l ight layer of brake The purpose of th_s _s to remove al l brake fluid

paste Screw in the pl ug (1 ) together with the

seal ing ring (2) The tighten _ng torque _s 1 _1 2

kpm (7_85 lb ft ).

6 Place the reta_ner (1 1 ) _n the housing (1 4) and

turn _t aCCording to F_g 5-41 PIace the reta_ner

(1 5) _n the spr_ng (1 O) and _nsert it in pos_tl On In _

the _ous_ng Now fit the housing to the hyd-

raul_ç part with the help of boltS. washers and _

nuts Z

F_g. 5_$l. _br8_ch u_lo_

l Secondary CirCuit from warn_ng valve

2 _eco,da,y c_,cu_t left front whel

3 Pr_m6y C_fCu_t from warning valve

4 Pr_m8y C_,Cuit left front wheel

f Pr_may circuit right front wheel

F_g. _. pig_o_ geg_ 6 SeConday c_rcuit r_ght front wheel

5 24

|