|

|

|

Begin OCR Text:

1 2 3 _ 5 6 _ _

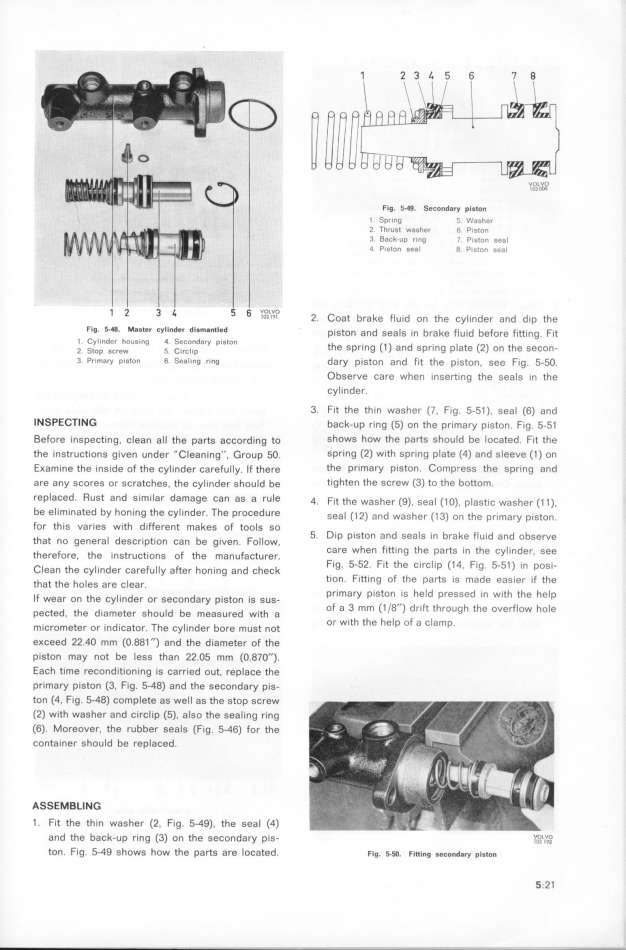

Fi$. f_49. Secondary piston

l Spring __ Washer

2 Thrust washer 6 Fig_o_

3. Back_up ring 7 PistDn geal

O Piston Seal 8 Pi,ton gea_

1 2 3 _ 5 6 _oLVo 2 C b

IO,I9I . Oat rake F_Uld On the CyjInder and dIF the

Fig_ f__ Ma9ter tylinder disnI8ntled p_gton and gea_g __n _,ake __u___ _eFo,e ___tt__ng F_t

l Cylinder housing 4 Secondary piston th . (_) d

U . '_ U (

U2) h

l '

_ __op ,e,,w _. _,,e_,_p e SpfIng an SFr_ng F ate On t e SeCOn-

3 PrimaY piston 6 Sealing ring da,y piston and f_t the pigton, gee Fig. 5-5O.

ObServe Care when inSeft_ng the SeaIS in the

cylinder.

3. Fit the thin washer (7, fig. 5-51), seal (6) and

INSPECTING back-up ring (5) on the primary piston. F_g. 5-51

Before inspecting. clean all the parts according to ShowS how the parts should be Iocafed. Fit the

the instruct_ons given under _Cleaning''. _,oup 5O. spring (2) with spring plafe (4) and sleeue (1) on

EKamine the inside of the cylinder carefully. _f there the pr_mary piston. Compress the spring and

are any scores or scratches, the cylinde, ghou_d be tighten the screw (3) to the bottom.

feFlaCed. Rust and s_milar damage can as a rule q. F_,t the waghe, (g), gea_ (_o). p_agt_,ç waghe, (__),

be eliminated by honing the cyl_nder. The procedure __ea_ (_2) and w'ag'he, (_3') o'n the p,__ma,y p,g'ton'

for this varies with different makeg of too_g go ' ' ' ' _

th t _ d b F __ 5. Dip piston and seals in brake fluid and obge,ve

a nO genera eSCrlptlOn Can e gIVen. o oW.

th F th . . F h F Care when fitting the parts in the cylinder see

ere Ore, e InStrUCtlOnS O t e manU aCtUrer. '

C_ean the çy_._nde, ça,eFu__y a Fte, hon._ng and çheçk Fig. 5-52. Fit the circlip (14. Fig. 5-51) in posi-

that the ho_eg a,e ç_ea, tion. fitt_ng of fhe parts is made easier if the

_F th _. d ' d F,imary piston is held pressed in w_th the help

Wear On e Cy In er Of SeCOn ary pIStOn IS SUS-

peçted the d,amete, ghou_d be meagu,ed w._th a of a 3 mm (t/8'') dr_ft through the overflow hole

. ' d Th _ d b or with the help of a clamp

mICrOmeter Or In ICatOf. e Cy In ef Ore mUSf not '

eKceed 22.4O mm (O.081'') and the diamete, of the

piston may not be less than 22.O5 mm (O.07O'').

EaCh time reConditioning iS Carried oUt. ,eplaCe the

Frimary piston (3, Fig. 5-48) and the seCondary pis-

ton (4, fig. 5-48) complete as weIl as the stop screw

(2) wifh washer and circlip (5). aIso the sealing ring

(6). Moreover. the rubber seals (Fig. 5-46) for the

container should be replaced.

ASSEMBLING

1. Fit the thin washer (2. fig. 5-49), the seal (Q)

and the back_up ring (3) on the secondary pis_ V,,O,L,v,o,

tOn. Fig. 5-49 Shows how the parts are located. Fig. _-_. Fitting seconday p_gton f_.21

|