|

|

|

Begin OCR Text:

_

_

/ _ _ 4. fif the fubbef šovefg on the p_ungef and houg-

Ing. FIt the jOCk f_ngS.

5. fit the brake padg. P_ace one of the fetaining

pins in posit_on and fIf the damping springs and ',

then the othef fetaining p_n. _ecufe the pins

with the hairpin-shaped retaining š_ipg. Chešk

that the pads are movable.

6. f_t the bleedš,_ nipp_es and a_go the brake ineg. '_

FITT__G __

1 . Place the caliper in position. Check that the _,

contact surfaces of the retainer are clean and

,,,o,,_v,,o nof damaged. Check the locat_on of the brake ,

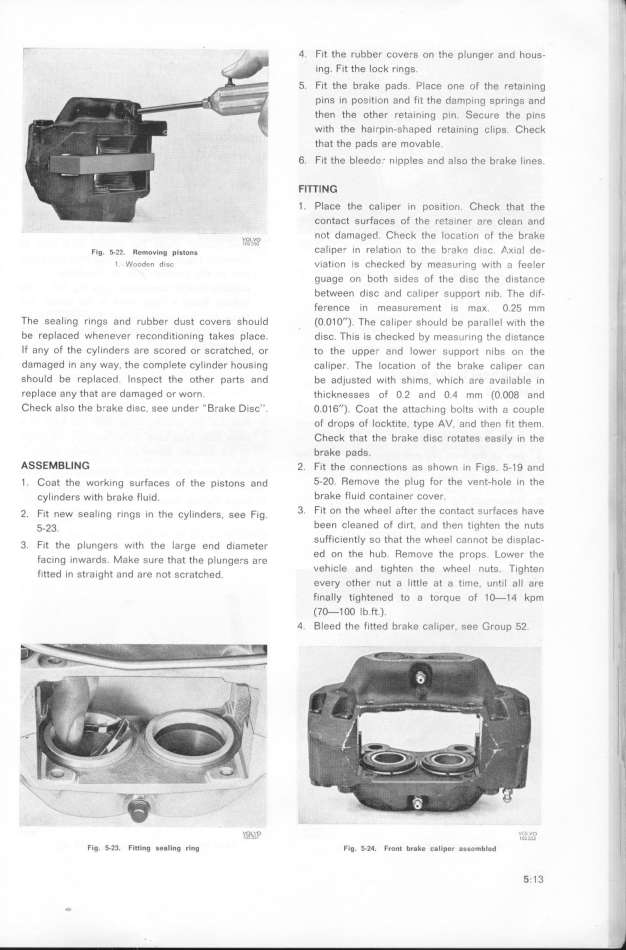

Fig. ____. ffe_ovi_g pig_o_g ' Calpef In relat_On tO the b_ak_. d_Sš _.K_a_ dg_ ',

1 Wooden disc viation is šhešked by me__g__.fino with a fee_ef __I

guage on both sides of the d_s_c the distance

between disc and cal_per support nib. The dif- _

FefenCe Ýn measurement _S ma_. O.25 mm

The SeaIlng r_ngS and fUbbef dUSt CoVerS ShoUld (O.O1 O''). The ša_ipef shou_d be para__e_ with the '__

_

ke fe__aše_ wkenevef fešon_ition_ing ta_eg p_aše __ __ _ _ _ _ _ _ t_ _. t

U _1 U _ U _ l . OlSC. l nIS IS CneCKeO Dy meaSUfIng ne OlS_ anšg

If any Of the CyIinders are sCored of SCfatChed, of to the uppef and _owef guppoft nibg on the

damaged In any Way, the COmplete Cylindef hoUSing ša_ipe_, . The _ocation of the bfake ša_ipef šan

ShOUld be feplaCed. InSpeCt the Othef parts and be adjugted with ghimg, which are avai_ab_e in

feplaCe any that afe damaged of Wofn. thicknesges of O.2 and O.4 mm (O.OOg and

CheCk aISO the b__ ahe d_SC, See under _Brake DiSC''. O.O16''). Coat the attašhing bo_ts w_th a coup_e

ol dropS of loCktite. type AV, and then fit them.

Check that the brake disc rotates easily _n the

bfake padS.

ASSEMBLl_G 2. Fit the šonnešfiong ag ghown in fiog. 5-1g and

1 . Coat the working gurfašes of the pigtong and 5-2O. RemOve the plug for the ven_t_hofe in the

cy_indefg with bfake f_uid. brake fIUld Containef CoVef.

2. F_t new sea__ng f__ngg _in the šy__ndefg, gee __g. 3, fif on the Wheel aftef the Contašt gurfašes haVe

5-23.

' been Cleaned of dirt, and then tighten the nuts

3 F h _ h h _ SUffiCiently So fhat the wheel šannot be disp_aš-

. It t e p UngefS W_t t e afgg end d_amgtef

F d _ k h ed on the hub Remove the props _owef fhe

aClng InWaf S. a e SUfe t at the p_Unggfg afg ' '

f d h d h vehicle and tighten the wheel nuts Tighten

Itte In Stfalg t an afe nOt SCratC ed. _

evefy ofhef nut a _itt_e ak a time, unt.i_ a__ afe

finally tightened to a torque of 1_14 kpm

(7_1 OO Ib_ft_)_

4. Bleed the fitted bfake ša_ipef, gee Cfoup 52. _

'_ _ _ g_____

=__.dq.,. _

_ -_ ,lOO5t_'_'Ol __Uu_l_,__Oz

Fig_ f2__ Fittin$ 8e8llng ring Fig. S_24. Front bra_e ealiper aggembled 5__ 13 _'__ _

|