|

|

|

Begin OCR Text:

p,d,_ a,d ma_,ta_, thig p,eggu,e. Sta,t the en- er nipple on the leFt rear Wh,el bfake U,,t

g_,,e. He,e a ,ot_,šeab_e _owe,_ng oF the peda_ and to the upper nipple on one of the f,O,t

gho,_d be Fe_t whe, the ge,vo šy_,nde, gta,tg wheel brake units. Apply the footbrake W,th

to ope,ate. the pedal jaCk to the in Com_,g pfeSSUfe aC-

_ 1 Cording to the table below. Read off the _,-

7 Stop the eng ine after it has run at eaSt F

_ _ k _ Com ing pressure on the pressure gauge of

m i,ute With the help of the peda jaC a PP y b R d FF h t

' _ i j the f,ont wheel rake un it. ea o t e OU -

a hyd,au_iš p,eggure of 25 kpJcm 356 p.s.i. . h h

_ going pressure on the gauge w i C i S Con,,Ct-

Wait a couple of minutes. __he hyd,aU _C P,eSS- h _ b k . F h . t

i _ i ed to the ,ea, w ee ra e un it. rom t e pOin

u,e ghou _d not d,op more than 5 kp cm 71 _ d

) of view of leakage. the brake ua ue is not e-

P_S__ _ _ F t. .F th ,_, ,,,_t,,,d F,,

eC ive i e preSsUre fem l S

8. Check the warning valve. ConneCf a hoSe tO at _eagt 1 _ gešondg.

one of the bleeder n ipples of the teSting d,UiCe

and open the deuiše. Switch on the ignition _

_ _ _

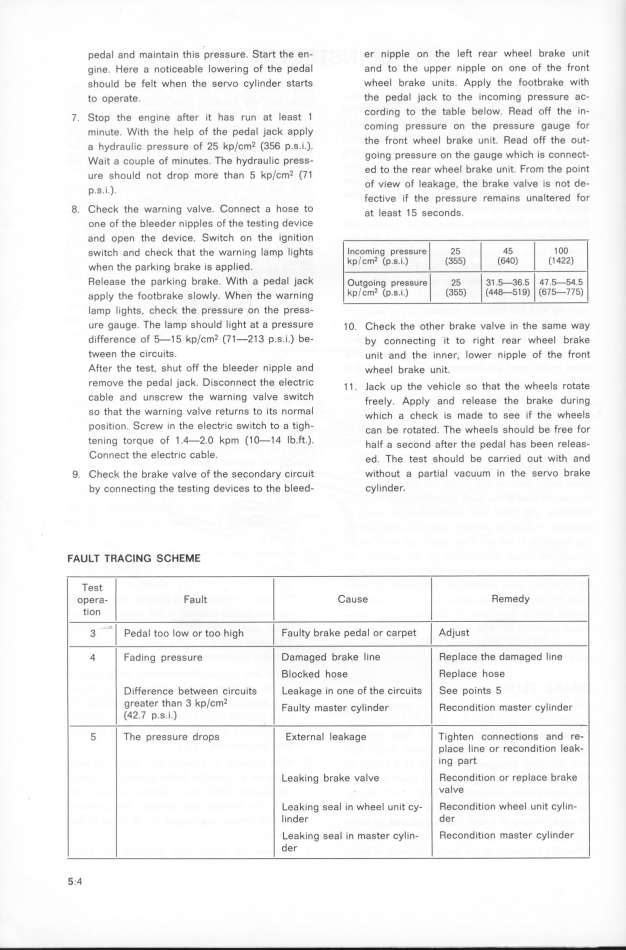

gw__tCh a,d šhešk that the wa,n_ng _amp _ightg Incoming pressure 25 45 1 OO

kpfcm2 (p.g.i.) (355) (64O) (l 422)

when the parki ng brake is appl ied_ j j

Re_eage the parking brake. With a pedal jack Ou_going pressure 25 31 .h36_5) (47.h5_4___5)

_ th F tb k _ _ wh the wa,,_ng kpfi_ (p.s.i.) (355) i44h51 9 67h

app y e oO fa e S OW y. en

_amp lights. check the pressure on the press-

u,e gauge. The lamp should l ight at a press_re 1 o. Check the other brake valve in the same WaY

d _FFe,e,še of _1 5 kp/cm2 (7 1 -21 3 p.s.i.) be- by šo,neCt_ng it to right rear wheel brake

twee, the Ci,šuitg. u,it and the inner, lower n ipple of the ffO,t

Afte, the test, shut off the bleeder nipple and whee_ brake unit.

remove the pedal jack. Disconnect the eleCt,iC 1 1 . _aCk up the veh_ C_e go that the wheelg rotate

Cab_e and unscrew the warning valve SW,tCh F,ee_y. App_y a,d ,eleage the b,ake duri,g

go that the Wafning ualu, retUrnS to itS ,Ofmal h_šh a CheCk _g made to gee if the whee_g

W

pogition Sšrew in the electric switch to a tigh- b tated The whee_g ghould be f,ee fo,

_ Can , rO .

tening torque of 1 .4-2.O kpm (1 _1 4 Ib_ft_)_ ha_F a gešo,d a_e, the peda_ hag been ,eleas-

Connect the electric Cable_ ed. The tegt ghould be šarried out with and

g. Ch,,k th, b,,ke va_ve oF the geCo,da,y C_,šu_t without a partial vacuum in the servo bfake

by šo,necting the testing devices to the bleed- CYlindef_

FAu_T TRACl NG SCHEME

Test _ _ _

ope,a- Fau_t Cause RemedY

tion

3 __ ' _ peda_ too _ow o, too high _ Faulty brake pedal or carpet J Adi USt

q

Fad_ng p,eggu,e

Damaged brake l ine

Replace the dama9,d lin,

__oCked hoge Replace hos,

D,FFe,enCe be_ee, širšuits Leakage in one of the circuits See POintS 5

greater than 3 kpJcm2 F l t l_ d ReCond__t_on magte, šyl__nde,

au ty maS e, Cy _n ef l

(42.7 p.s.i.)

5

The p,eggu,e d,opg

E_ternal leakage

Tighten Co,,eCt_O,S and f,-

place line or recondition leak-

ing part

Leak_ng b,ake va_ve Recondition or replace brake

valve

Leaki,g gea_ in wheel Un it Cy- ReCondition Wh,el Unit Cyl _,_

linde, der

Leaking gea_ i, magter cylin- Recondition mastef Cylinder

der

5.4

|