|

|

|

Begin OCR Text:

__

_

_

P l2O, P l8OO

CHANGING WHEELS

When Fitting wheels it _is importont thot oll grit

ond dirt ond ony surplus point is cleoned oFf

From the contoct surfoces between fhe wfeel ond

hub.

I REPLAtING 7HE WHEEL s7UDS

When replocing o wheel stud. the old one is

pressed out. oFter which on oversized stud is

fitted. Before o new stud con be pressed through

the broke d'isc hoIe. fhis must be drilled out to

l6.6-l6.8 mm. On the reor wheel hub the wheel

stud con os o rule be fitted without drilling out

_ f f _ VOlVO

t e o e. 26p_

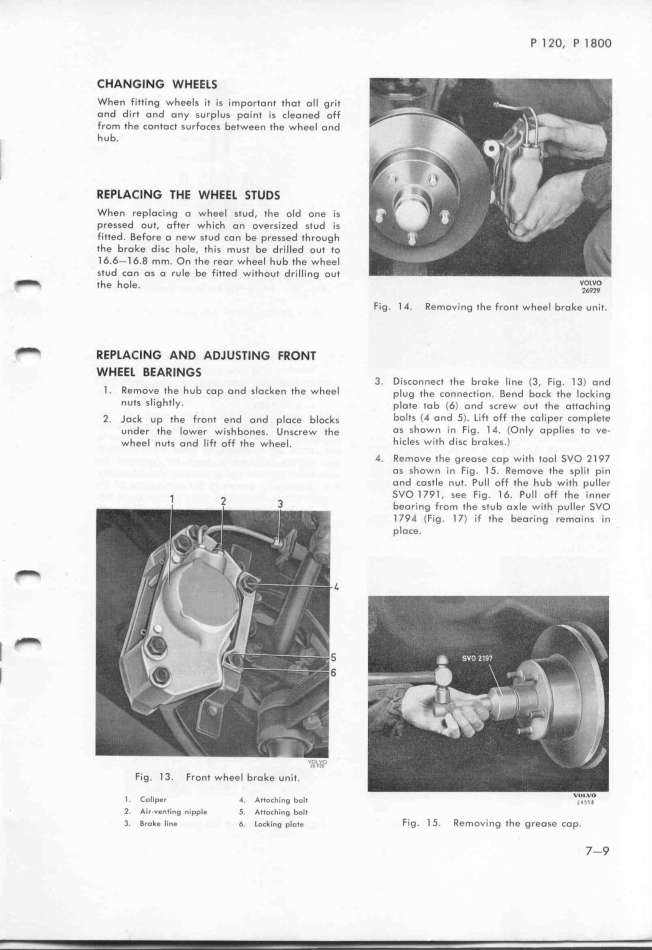

Fig. l4. Remov_ing the Fronf wheel broke unit_

_ REpLAclNG AND AD_us7lNG FRoNr

WHEEL BEARINGS d

3. Disconnect tfe broke line (3. Fig. l3) on

l. Remove the hub cop and slacken the wheel p_ug the connection. Bend bock the lock_ing

nuts slightly. plote tob (6) ond screw out the ottoch_ing

_ _ k tf F t d d _ bi k boIfs (_ ond 5) LiFt off the calipef Complete

. oc up e ron en on p oCe oC S ' _ i

d tf i _ fb u tf, os shown in F_ig l4 (Oi_ y opp ies to ve-

U, er g oWer W_s Ones, n5CreW f _ f d b' k ' j

wfe,i ,,t, ond i_,Ft oFF tf, wfee_ ices wit isc ro es_

4. Remove the greose cap with tool SVO 2l_7

os sfown in fig. l5. Remove the split pin

ond costle nut. Pull oFF the hub with puller

SVO l7_l. see Fig. l6. Pull oFF the 'inner

beoring From the stub oKle with puller SVO

l7_4 (F_ig. l7) if the beoring remo_ins 'in

P_OCe_

'_O_t_'

Fig l3. front wheel broke un_it.

_ _o_iper _ Attocfing boIl VlUll?_V'tO

2 A_r_ent_ng nipple f Attoching bolt

3. g,o_, _,_e _. _o____g p_o_e Fig. l5 Removing the greose Cop_ 7-_

|