|

|

|

Begin OCR Text:

P _ 2 O, P l 8OO mm (O.Ol 2_O. O2 O'') i nside the outer foce

with the help of drift SVO 2498. see Fig . 45.

Check the fit of the shoft in the beorings or

bushes respectively. 7he shoft should turn

eosily but without ony ploy.

On type l l l the bushes ore reomed with

reo mer SVO 4l 53.

2 . Fill the beori ngs ond the spoce between

them with chossis greose. Also Iubricote the

vulcollon woshers on both sides.

3 . Fit the other ports os shown i n Figs. 24_26.

The nu1 is tightened to o torque of 8.5 kg M

(6O Ib.ft.).

t. After osse Mbling there must be no ploy i n

the beori ngs. When odiusted cDrrectly. o _

_ _ _ _ + _ k ( _ 3 + 4 3 _b _

, o_ j turni ng torque o - gcm - _ _

_V ' in.) is required. For e_omple, when pul li ng

_ on the reloy orm ot the steering rod hoIe

i ' (the inner hole) ot right_ong Ies. o spri ng_

i ,_. bolonce shou Id give o reod ing of O.7- l .3 _

_ kg ( _ ._4-2. g6 ib.). If th is result is not ob- _

_ i toi ned when checking, the beori ng Mount-

!, ings m ust be token oport o nd odi usted with

gh ims of su ito ble thickness.

'__ When the correct torque hos been obtoined

, the split pi n or ci rclip respective Iy is fifted.

, '___ On lote production type l l l there is no circli p.

VOtVO

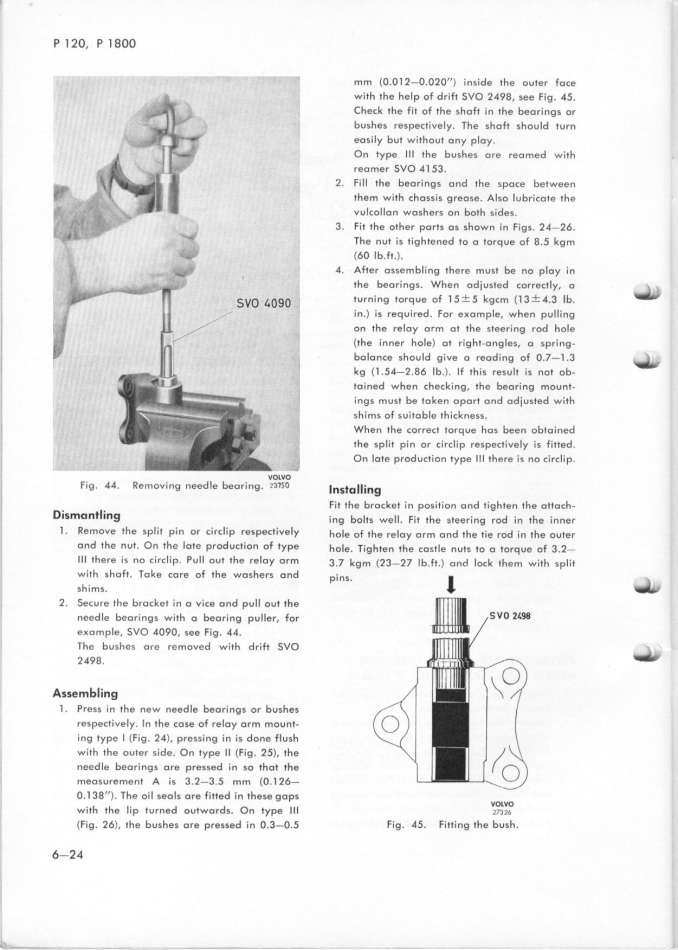

_ Fig 44 _e__oving need_e beo_i ng 13l50 _ _ ___ *

_, _ _ _ __S O__iII_

! fit the brocket in position ond tighten the ottoch-

DiSmo Ittli_g i ng bolts well. Fi1 the s1eeri ng rod in the i nner

l . Remove tfe split pin or ci rcli P respectively hole DF the reloy orm ond 1he tie rod in 1he outer

ond the nut. On the lote production of type ho_e. _ighten the cos1le nuts to o torque of 3.2-

Ill there is no circlip. Pull Dut the reloy orm 3._ kgm (23-2_ _ b.f_.) ond _ock them with split

with shoft. 7oke core of the woshers ond p__ ff_. _ _

,h ;m,. _ _

2. 5ecure the brocket i n o vice o nd pull out the

needle beori ngs with o beoring puller. for

e_omple. SVO 4O9O. see fig . 44.

The bushes ore removed with drift S_O _

2498. _

AS6embli_g

l . Press i n the new need le beorings or bushes

respectively. In the cose of reloy orm mount-

i ng type l ( Fig. 24). pressing i n is done flush

with the outer side. On type tt ( Fig. 15), the

need le beori ngs ore pressed in so thot the

meogu_ement A is 3.2-3.5 mm (O. l 26-

O l 38'') The oil seots ore fitted in these gops

' _ VOtVO

with the lip turned outwords. On type l l l _73_6

(F_g . 26), the bugheg o_e p_egged i n o.3-o._ Fig. 45. Fitting the bush.

_-24

_h __ = . . . ..- . .- _ - - _ __

|