|

|

|

Begin OCR Text:

p 1 2O. P 1 8OO

_. _ack up fhe rea, end and place blocks under Dl_M_H_LlHO

the rear a_le. Release the handbrake_ _. Sc,ew off fhe cap (2, Fig. 7 and l7) and empty

2. Rofgte tfe wheel while applying the brake5 o,f fhe brake fiuid.

by fu,ning fhe adjusfing screw clockwise with 2 p ii b k fh ubber cover <6) and remove ffg

. U aC 8 r

the help of spanner SVO 25_a. see Fig_ l6 c__rcjjp (7), washer (g) and thrust rod (5). Shake

When fhe wfeel can only just be turned round o,t aii fhe parfs from fhe cyiinder. see Fig. 27.

wjth one hand. stop turning the screw_ Then

ease off four ''notches'' and check that the

brake orum can rotate freely w'ifh the ad_ _HSpE___HO

justing screw in the locked position_ f . ii f f th + i_ d r

h h i . h Bg ore inspecting. a par s o e mas er cy in 0

3. Adjusf +he ot er rear w ee in f e Same way_ b h d th i f d . .f

h shouid e was e in me y a e spiri _

Lower t e Cal_ e . fh i. d f ii _ + ii _hgre

_amine e cy in er care u y in erna y_

mus+ be no scoring. scrafches or rust on the polished

surface. Such damage can as a rule be eliminated

by foning the cylinder. The procedure Ior dOing

fhis varies with different makes of tool so fhat no _

i d _ f_ b _ __h f foitow

genera eICrip ion can e giVen_ ere Ore

ffe manufacturer's instructions. Clean the cylinder

carefuiiy alter honing and check that the holes afe

clear.

_he clearance between the plunger and cylindef _

musf nof e_cegd O.2O mm (O.OO8''), Il the cleBrance

e_ceeds this value, test with a new plunger_ Il

this does not help, the master cylinder must be

replaced.

Replace botf the plunger seals. Any otfer parts

'i_'__'4'_'i which are dBmag8d or worn should be rep1aced_

Fig. 26. Adjusting the wheel brake unit_ _SSEM_LIHO

MaIleI _yliIldeI 1 . Fit the wasfer (15. Fig. 2J) in the botfom ol

. observe the ufmosf côre when working on the the cylinder_

hydraujjc sysfem Wash the hands with soap and i 6

_ _ _

1

wafer beEore cleaning fhe infernaI parts_ The5e _ ,

shouid be cleaned with methylated spirit_ Petrol _

(gasol_ine). paraffin (kerosene). trichlorethylene of _

any o+her spirjf containing bensol must not be used_ .

only fiii with a first-class brake fluid which fulfils

fhe ,equiremgnfs of SAE 7O R 3. Fluids which only

l

fuifii fhe requiremenfs ot SAE 7O R 1 . or what is _

known as HD quality, must not be used, Avoid

,_ '

spjjiing brake fluid on the painfwork as fhis can

cause damage. ,

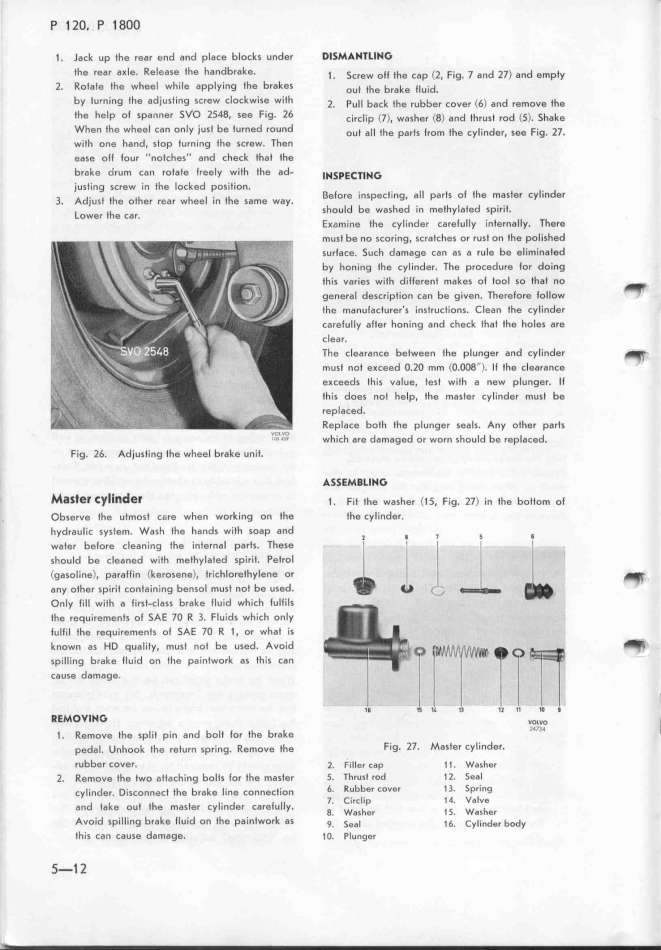

_i _i _i _3 1_ 11 10 9

QEMO__HO vo_vo _

h b k __734 _

_. Remove fhe splif pin and bolt for t e ra e

d i u h k th f _ Remove the Fig. 27. Masfer cylinder_

pg a . n oo e fe Urn Iprlng_

rubbgr cover. z. filler cap 11 _ Washer

l. Remo,e *he fwo ,ff,,hing boifs Eor fhe masfer 5. Thrust rod 1l_ 5eal

i d D. f +h b k i_ f_ 6 _ubber Cover 13_ 5pring

cy in er. isconnec e ra e Ine COnneC lOn ' j _4 v j

h i. d f ii _. Circ ip . _ ve

and fake out t e master cy in ef Cafe U y_ g w _ j5 w ,he,

. a, er . a

Avojd spilling brake fluid on ffe paintwork aI q. _ea_ j6. Cylinder body

fhis can cause damage, tO_ Plunger

5-1 2

|