|

|

|

Begin OCR Text:

_ _ _ _ _

P 1 2O, P t 8OO, PV _44

dismantling and then fit the tront pinion bearing pinion gauge sfould be higher than Ihe adjusfer

(2J). Fif the wrench SVO l4O4 and the press fi_ture. and if it ís marked '' -_ '' the pinion

fool SVO 1845 on fhe front end of the pinion gauge should be lower than the adjuster ti_-

and puII in the pinion. see Fig. l3. ture when adjustment is correct.

5. Replace the press tool SVO 1 845 wifh a washer

and nut. Tighten the nut fo a forque of l8-3O

kgm. (lOO-22O Ib. ft.). Then check the pinion

begring tension. It should be reIatively easy to

rofate the pinion (1 1 .5-23 kgcm = 1 O-lO

Ib. in.). There should be no looseness. Bearing

fension is adjusted by means of shims (26) on

the front pinion bearing.

6. There should be a cerfain nominal measurement

(A, Fig. 24) to the centre line of tfe crown

_ wheeI. Due to tolerances _in manufacture. how-

ever, there are deviations trom this nominal

measurement. The deviation is shown on the voivo

d _ _ h . . b _ 2t53t

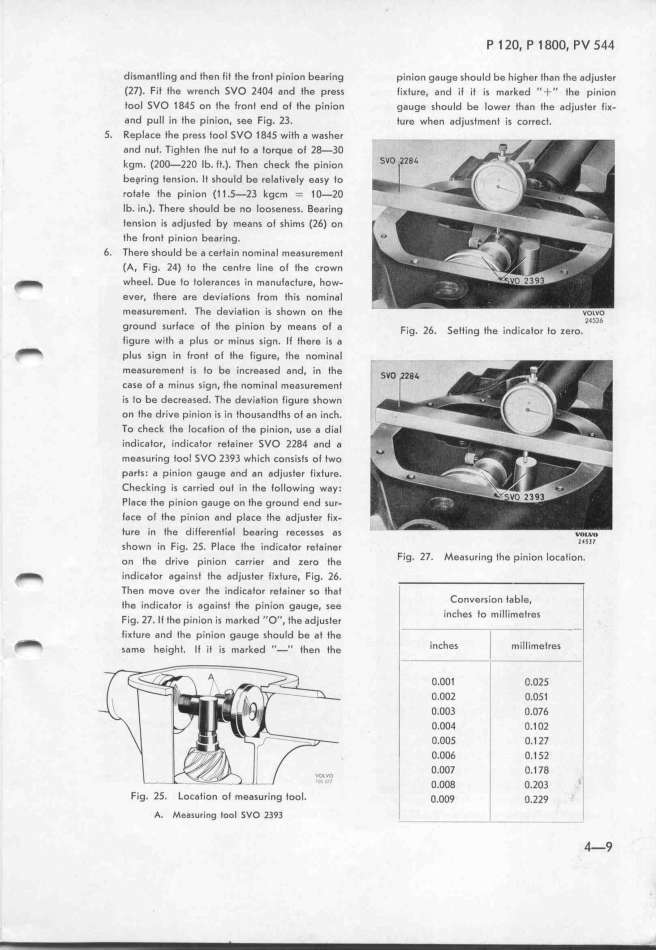

groun sur ace o t e pinion y means o a F_,g. 26. Se___,ng _he _,nd_,ca_or _o zero.

tigure with a pIus or minus sign. If there is a

_ plus sign 'in fronf ol the figure. the nominal

measurement ěs fo be increased and, in the

case of a Minus sign. the nominal measur8ment

is to be decreased. The deviation tigure shown

on the drive pinion is in thousandths ol an inch.

To check the location ol the pinion, use a dial

indicator. indicator retainer SVO 2l84 and a

measuring tooI SVO l393 which consists of two

parfs. a pinion gauge and an adjuster ti_ture.

Checking is carried out in the tollowing way.

Place the pinion gauge on fhe ground end sur-

face of the pinion and place the adjuster tiK-

ture in the differential bearing recesses as ____

h h d Zl5Il

s own in Fig. 25. P_ace f e in icator retainer

on _he dr.,ve p.,n._on carr.,er and zero _he Fig. l7. Measuring the pinion location.

_ índicator against the adjuster fi_ture, Fig. 26.

Then move over tfe indicator retainer so that _ _

_

Conversion table,

the indicator is againsf the pinion gaUge, see

k d ,, , h inches fo millimetres

Fig. 27. l I the pínion is mar e O' , t e adjuster

fiKture and tfe pinion gauge should be at the _ i - - -

_ same he_,gh_. __ ___ _,s marked ,,_., _hen _he

inches _ miIlimetres

O,OOf 'li O.O25

O.OO2 _ O.O51

O.OO3 _ O.O76

O.OO4 O.1 Ol

O.OOS

O.1 27

, O.OO6 O.1 5l .

i o.oo7 o.1 J8 l

_

O.OO8 O.lO3

Fig. 25. Location of measuring tool. o.ooq _ o.zzq

A. Measuring tool sVo _393 - - ' - l

4-9

|