|

|

|

Begin OCR Text:

_

_ 1 2O, P 1 8OO

e_amj_,e the support bearing by pressing the bearing A

,,,e, ,g,,,,i e,,h oi_,e, w_,ff ihe h,,d, ,,d f,,,_,,g _

theM j, opposite directions. The bearing should run

ea,ily without binding at any point, Il nof, scrap the (',

be_ring and replace iI wilh a new one_ _(1'

_ j_

_SSEM_Ll__ 1_ j _

_IIem_li_g the u_iveIIoI ioi_tI (' _

_ . Fit ,ew corl_ washers on tfe spider frunnions_ ti'

Fif ihe ,p;der i, the driving yoke in Ihe same

position as it was beIore being removed_

_. pu,h over fhe 5pjder i, one direction so far thai

ihe ,eedle beari,g ,an be litted onto the -

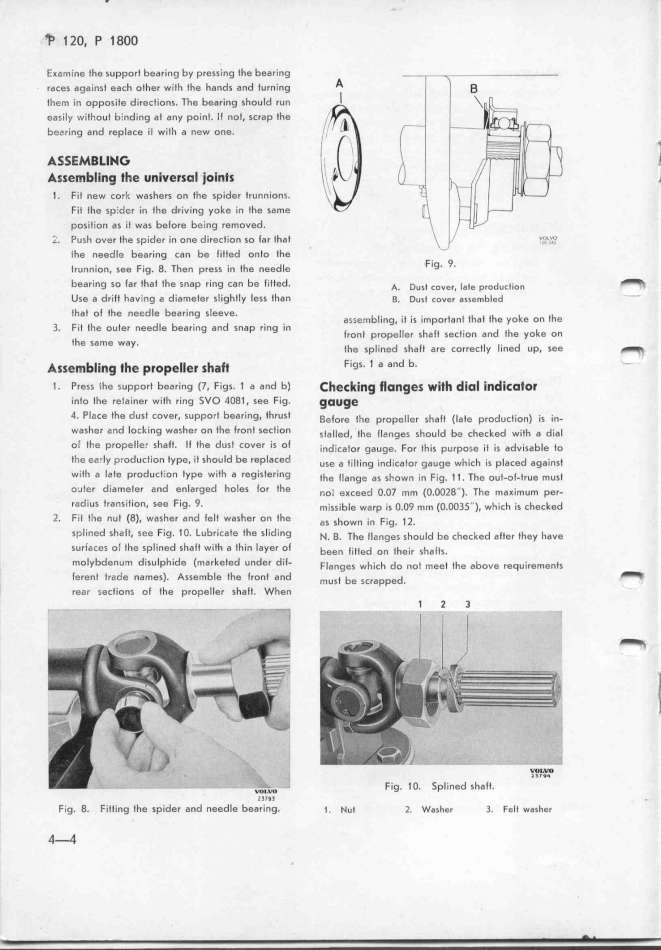

th d_ Fig. 9.

frunnion, see Fig. 8. Then press in e nee e

b _,g ,o fgr ihaf ihe snap ring can be fitted _ D t t i d t teaFl _ . u5 covgf, a e _lO UC lO_

U,e a drjff faving a diameter slightly less than B. Dust cover a55embled

that ol the needle bearing sleeve_ b__ _t _ _ i t ff f fhe yok, o, fhe

a_,em ing, i is impor an a

3 Fjf fhe outer needle bear_ing and snap fing in _ t __ h ff t_ d tfe yoke o,

_ ,o, p,ope e, s a SeC ion a,

1he same waY_ fh __ d h ff i_y t_,ed up ,ee _

e ,p ,,g 5 a are COfreC ,

_ b__ th __ h _l F_gs. 1 a and b_ _

IIe_ i_g g _IO_e eI I a

1 . press _he supFori bearing (_, Figs. 1 a and b7 CheEkí_g _lo_geI __th diol i_díEOlOI

j,fo Ife retainer witf ring SVO 4O81 , see Fig_ gO_gg

4. Place the dust cover, support bearing, tfrusf _efo,e ffe p,ope__e, ,haff (late produ,tion) is in-

washer and locl_ing washer on ihe front sectio_, ,tatted, fhe f_g,ge, ,hould be checked with a dial

o'i fhe propelle: shaft, tf the dusl Cover i5 ol jndi,afor gauge. Fo, thi, purpose it is adv'isable Io

the early µroducfion type, it should be replaced u,e a ijtt__,g,,d,,ato, gauge whi,h is placed against

wifl, a late production type with a Fegi5tering ffe fta,ge as ,_ow, in Fíg. 1 1 . The out-ol-true must

o__ter diameIer and enlarged holes lor the ,o; e_,eed o.o_ mm (o.oo_g''). The Ma_imum per_

radius 1ransition, se8 Fig_ 9_ Mj,,,b_e wa,p js o.oq mM (O.OO35' ), which is checked

2. Fii the nut (8). washer and lelt washer on the ,, ,how, ,_, F_,g. 1 _.

splined shaft. see Fig. 1 O. Lubricate the sIiding _. _. The fta,ge, 5houtd be ,he,ked affer ihey have

sur(òces of the splined shalt wilh a thin layer ol bee, fjtfed o, tfejr ,haft,.

n_olybdenum disulphide (marketed under dil- Fta,ge, wf_,h do nof ,_eef the above requirements

fere,_ i ade ,ame,) A,,embte ife f,o,t a,d b d _

r _ inusf e scrappe ,

re_r section__ ol the propeller shalf_ When

_ . - _

1 2 3

_

______

Fig. 1 O. Spl_ned ,halt_

WLVO

_JJ9I _

Fjg. g. FiItíng the spider and needle bearing_ l . Nut __ Washer 3_ Felt Wa5h''

4-4

|