|

|

|

Begin OCR Text:

_

_

__ _

P 12O, P 18OO

W2lL7Yl5O

_ Fig. 28. Fitting tfe front housing h8If

f marks. On late production the washer _s se-

cured witf a circlip, see Fig. 24.

_ 5. Press the needle bearings (39) into the planet

vo_w gears (38) with drift SVO 2417. The bearings

Zl_9J ghouJd come gJ__ghtJy __ng__de _he g__de gu,Faceg

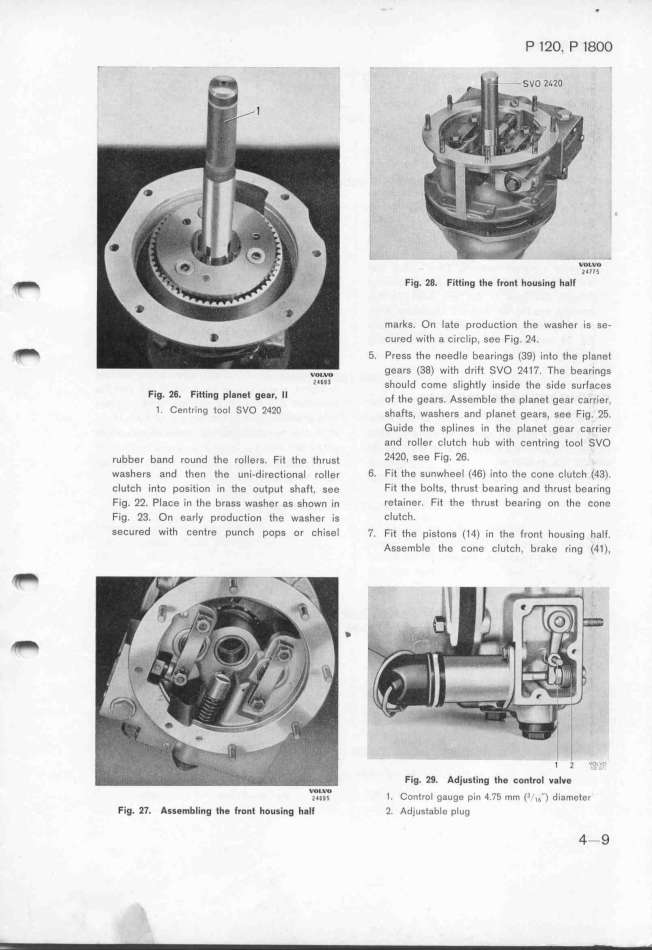

Fig_ 26_ Fitting plan$t ge8r_ Il oF the gea,g. Aggemb_e the p_anet gea, ca,,_e,,

1. Centring tool SVO 242O gha_g. waghe,g and p_anet gea,g, gee F__g. 2_.

Guide the splines in the planet gear carr_er

and roller clutch hub with centring tool SVO

,ubbe, band ,ound the ,o__e,g F_t the th,,gt 242O, see Fig. 26.

washers and then the uni-directional roller 6_ Fit tl_e sunwheeI (46) into the cone clutch (43)

clutch into position in the output shaFf, see Fit the bolts, thrust bearing and thrust bearing

Fig. 22. Place in the brass washer as shown in retainer. Fit the thrust bearing on the cone

Fig. 23 On early production the washer is clutch.

secured with centre Punch pops or chiseI 7. Fit the pistons (14) _n the Front houging ha_F.

Assemble the cone clutch, brake ring (41),

_

1 _ _____'

Fig. 29. Adjusting the control v8lve

viOiC6_g 1. Control gauge p_n 4_i5 i__ (3 _6 ) dia_ete,

Fig_ 27_ Assembling th_ tront housing half 2 Ad_ustahle plug 4-9

|