|

|

|

Begin OCR Text:

w_v__

o___

_)___

____

,__

__

P 12O, P 18OO

Check the cylinders of the control pistons for

scor_ing and wear.

Make sure that the oil passages are clean.

ASSEMBLING THE OVERDRIVE

1. Place the front circlip for the bearing (28) in

the rear housing half. Press in the bearing with

drift SVO 2413.

2. Press the pilot bearing (31) for the gearboK

, V,O,C,_,,O mainshaft into the output shaft (25) with drift

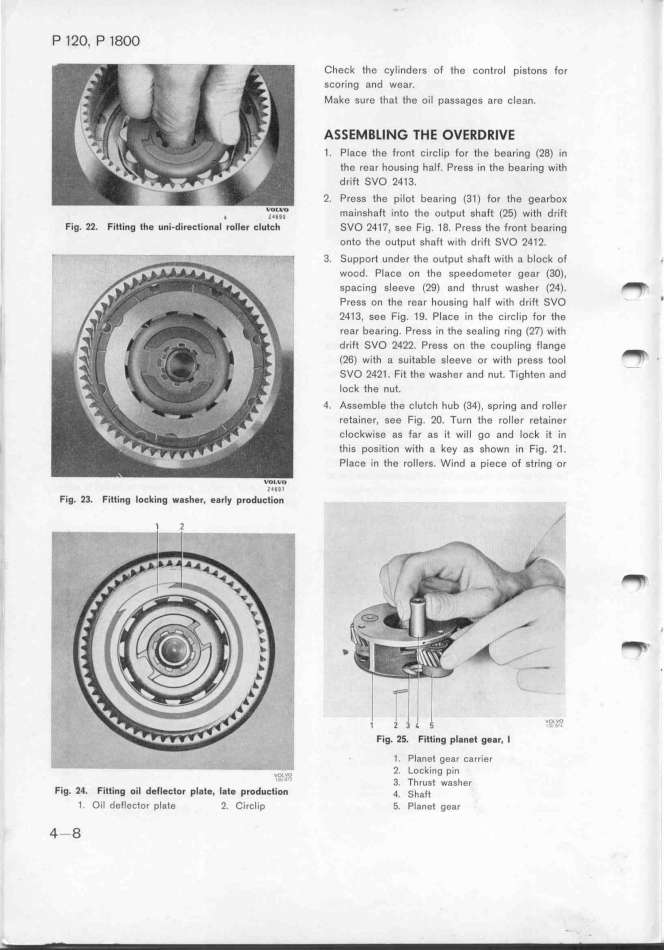

Fig. 22. Fitting the uni-directional roller clutch SVO 2417, see Fig. 18. Press the front bearing

onto the output shaft with drift SVO 2412.

3. Support under the output shaft with a block of _

wood. Place on the speedometer gear (3O),

spacing sleeve (29) and thrust washer (24). _

Press on the rear fousing half with drift SVO '

j

' 2413, see Fig. 19. Place in the circlip for the

rear bearing. Press in the sealing ring (27) with

drift SVO 2422. Press on the coupling flange _

i (26) w_i_h a su_j_ab_e s_eeve or w_i_h press _ooi _

l SVO 2O21. Fit the washer and nut. Tighten and

lock the nut.

4. Assemble the clutch hub (34), spring and roller

retainer, see Fig. 2O. Turn the roller retainer

clockwise as far as it will go and lock it in

_ this position with a key as shown in Fig. 21.

Place in the rollers. Wind a piece of string or

Fig. 23. Fitting locking _asher, earl_ produc'ti'o'n'

,

t 2 .._g3

/

i.___

.-!..._.,_ _

___ _,

_,, _ __

'

_ _I___ _

Fig. 2f. Fitting planet gear, l

1. Planet gear carrier

vu_,,o' 2. Locking pin

'' ' 3. Thrust washer

Fig. 24. Fitting oil de_l$ctor plate, late production q. __a__

t. Oil deflector plate 2 Circlip 5. Ptanet gear

4-8

|