|

|

|

Begin OCR Text:

__

P 1 8OO

- _ - - VOtVO

2652B

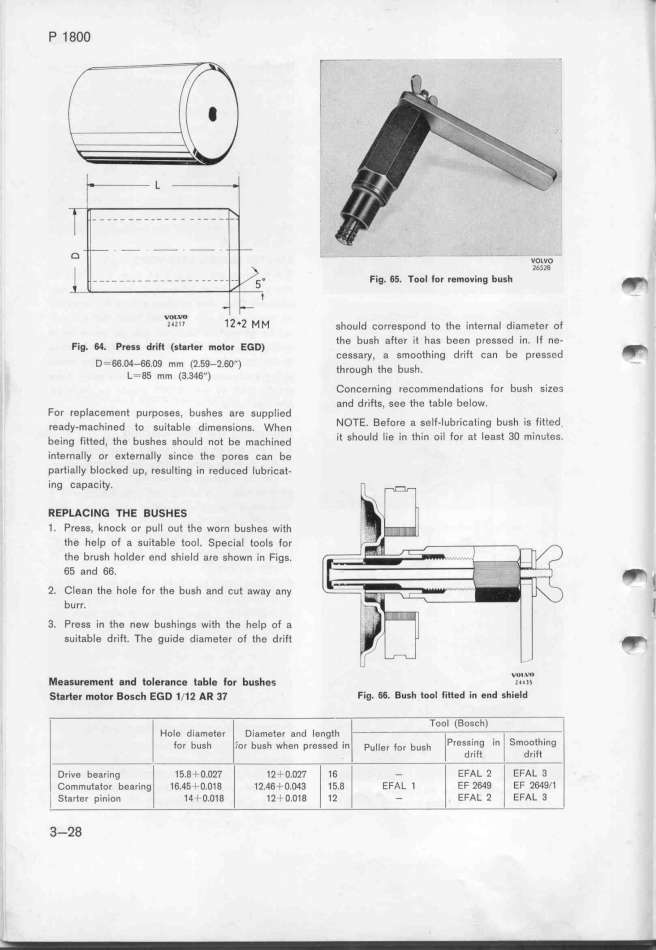

Fig. 65. Tool for remo_ing bush _

_1OiLiWi i 1 2 _2 _ _ gho,_d co,,egpo,d jo jhe ;,j,,,a_ d;amejer o_

the bush after it has been pressed in. If ne-

Fl0. %. P_eSS d_i_ (Stal4er motor EG_) _

cessay, a smoothing drift can be pressed

D -_66.O4-66.O9 mm (2.59-2.6_') jh,ough jhe bugh -

L-= 85 mm (3.346'') '

Concern_ing recommendations for bush sizes

and drifts, see the table below.

For replacement purposes, bushes are supplied

,eady.mach_,,ed jo gu__jab_e d_,me,g_,o,g. whe, N OTE. Before a self_lubricati ng bush is fitted

be_ g __jj d jh b h h _d j b h_ d it ghoUld lie in thin oil for at leaSt 3O min UteS.

ln l e , e U S eS S O U , O e maC Ine

internal Iy or e_ternal Iy since the pores can be

partial Iy blocked up, resulting in reduced Iubricat-

ing capacity.

REPLACIMG THE BUSH ES

1 . Press, knock or pu Il out the worn bushes with

the help of a suitable tool. Special tools for

the brush holder end shield are shown in Figs.

65 and 66. _ _

2. Clean the hole for the bush and cut away any '

burr. J

3. Press in the new bushings with the help of a

suitabIe drift. The guide diameter of the drift _

_gggure_e__ g_d _o_erg__e tab_e _or bug_e_ _zU_'_'_)'_s

S_g_er _otor Bog__ EG D ___2 Aff 3_ Fig. 66. Bush tool fiHed in end shield

_ _ _ oDl (Bosch3

_

_ HoIe diameter _ Diameter and length _

-_

_,, b,,_ ;o, b,,_ w_,, p,,,,,d _,, p,__,, _,, b,,_ Pressing in Smoothing

d rift drift

Drive bearing _

15.8 t O.O27 _

1 2-I O.O27 _

1 6 _

- _

' EFA L 2 _

E FAL 3

_ommu_gto, bea,ing 1 6.q5+ O.O1 g 1 2.46 + O.O43 1 5.g E FAL 1 E F 2649 EF 2649(1

_ Starter pinion 14 _ O.O18 1 2 ' O.O1 8 12 - EFAL 2 EFAL 3

3-28

|