|

|

|

Begin OCR Text:

_

P

Z

3

4

5

6

7 .

t 8

, 9 VO_vo

._ 26J72

Fig. 2O. Levers 8nd springs.

1_ Attachment for choke 5. Lever for fa_t id_i,g,

control outer casIng etc. _ --- vo_uu _

2_ Throttle flap spindle G. Lever for lowe,i,g je_ ___6__

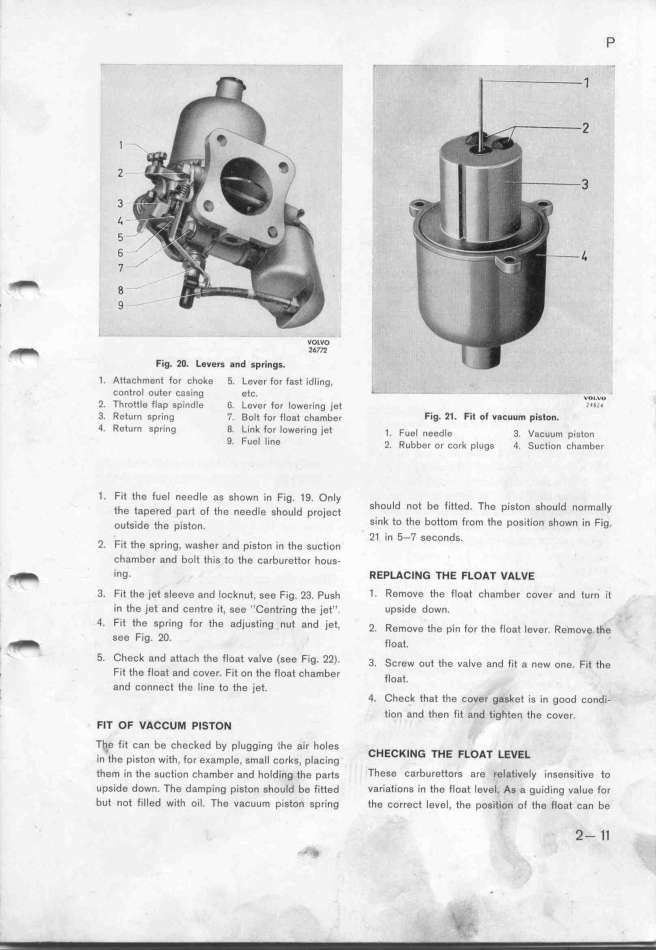

3_ Refurn spring _i. Bolt for float cha_ber Fig_ 21_ Fit ot va_uum piston.

4 Return spring 8. Link for lowering jet _. Fuei ,eed_e 3 vacuu_ p,et,,

9. Fuel line _. Rubbe, o, co,k p_ugs 4 _uct__o, c_ambe,

1 _ Fit the fuel needle as shown in Fig. 1g. O,Jy h _d

ehe tape,ed pa,e oF ehe ,eedie Shou_d p,oj.e,e S ou not be fitted. The piston should normally

oueSjde the p_,Seo,. sink to the bottom from the position shown in Fig.

2 F. h 21 in 5-7 seco,ds.

_ it t e spring, washer and piston in the suction

chamber and bolt this to the carburetto, hous-

_ ing. ffep_C___ THE FLoAT vALvE

3_ Fit the jet sleeve and locknut, see Fig. 23. _ush 1_ Remove the float chamber cover and turn it

in the jet and centre it, see ''Centring the jet'' upside down.

4_ Fit the spring for the adjusting nut and jet 2 R eh , F eh Fi e _ R h

, _ emOVe e pl, O, e Oa eVer. emOVe t e

see Fig 2O Fi

, _ ' ' Oat.

5, Check and aMach the float valve (see Fig. 22). 3. _,,,w ,,e eh, ,a_,, ,,d F.,e a ,,w ,,, F.,e th,

_ Fit the float and cover. Fit on the float šhambe, F_ '

d Oat.

. an connect the line to the jet. 4_ Check that the cover g8sket is in good condi-

tion and then fit and tighten the cover.

FIT OF VACCUM PISTo_

Th,e fit can be checked by plugging ihe air holes CHeCKI__ TH

_ eh _ e _eh F i _i k i . E FLOAT LEVEL

In e pIS O, Wl , Or eKamp e, Sma Cor S, p aCIng

them in the suction chamber and holding ehe pares These carburettors are relatively insensitýve to

upside down. The damping piston should be fitted variations in the float level. As a guiding value for

but not filled with oil. The vacuum piston spring the correct level, ehe pogjtţo, oF ehe Fioae ,a, be

2- 11

= _

|