|

|

|

Begin OCR Text:

_

_

_

P

ff E PA l ff l N _ T ff U _ T l O N _

The repair instructions below only concern the oil tions, please refer to the Service Manual for the

cooIer and carburettors. For other repair instruc- B 18 A engine.

_EPLAC_N_ THE OlL COOLER (_ _8 _) 7. Start the engine and check for leakage.

1_ Drain off the engine coolant_ g. _i _he nipp_e (3) has been repiaçed, _he new

2. Disçonneçt the çooiant çonneçtions on the oi_ one should be tightened to a torque of 45-5_5

cooIer. Remove the oil fìlter. kgm (33-4O Ib.ft.).

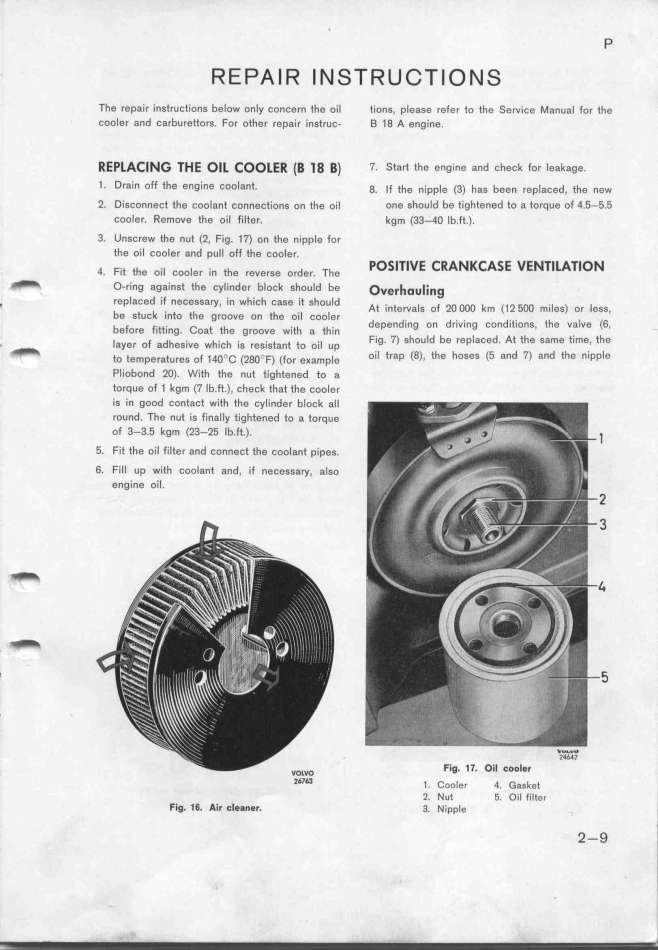

3. Unscrew the nut (2, Fig. 17) on the nipple for

the oil cooler and pull off the cooler. PO_lTIVE CRANKCASE VENTILATlON

4. Flt the OIl COO_er In the feVerSe Order. __he

_ O-ring against the cylinder block should be ove__o__i_g

repIaced if necessary, in which case _it should At . t i i 2oooD k (_2 5oo _i ) _

l in erva g o m ml eS Or eSS_

be stuck into the groove on the oil cooler d. . h i (6

b depending on driving con itions, t e vave ,

efore fitting. Coat the groove with a thin h

i dh h Fig 7) should be replaced. At the same time, t e

_ ayer of a esive w ich is resistant to oil up '

_ t t t i _4o__ (2go F) (i i oil trap (8) the hoses (5 and 7) and the nipple

O empera ureS O _ Of eKamp e '

PliDbond 2O). With the nut tightened to a

torque of 1 kgm (7 Ib.ft.), check that the cooler

is in good contact with the cylinder block all

round. The nut is finally tightened to a torQue

of 3-3.5 kgm (23-25 Ib.ft.).

5. Fìt the oiI filter and connect the coolant pipes.

6. Fill up with coolant and, if necessary, also

engine oiI. __U____p

Fig. 17. Oil _ool_r

267_ _ _ _ q _ k _

. oO er . aS e

2. Nut 5. Oil filter

Fig. 16. Air _l_an_r. 3. Nipple 2-9

|