|

|

|

Begin OCR Text:

_

P

_)

_ _

Fig. 85. Removing thg hub __'''_ _

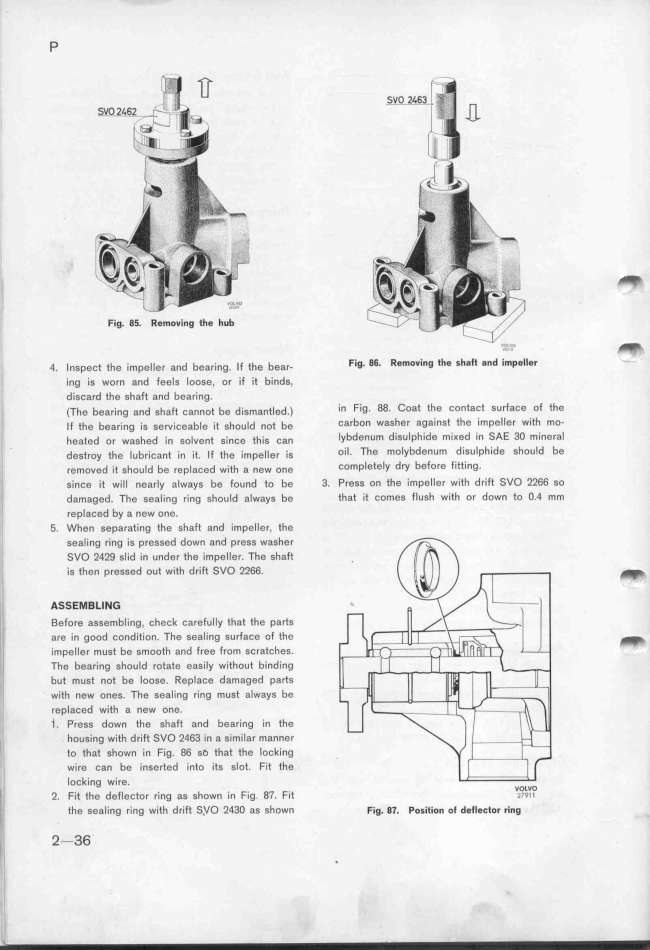

4. _ngpec_ _he impe__e, and beari,g. _f the bear- Fig_ 86_ R$moving the _hatt and impeller

ing is worn and feels loose, or if it binds.

discard the shaft and bearing.

(The bearjng and gha__ ca,,ot be digmant_ed.) in Fig_ 88_ Coat the contact surface of the

_f the bearjng ig ge_iceab_e it ghou_d not be carbon washer against the impeller with mo-

heated or waghed in go_vent g_nce th_g can Iybdenum disulphide mi_ed in SAE 3O mineral

dggtroy the _ubricant in jt. _f the impe__er jg oil_ The molybdenum disulphide Should be

,emoved it ghou_d be rep_aced with a new o,e completely dy before fitting.

since it will nearly always be found to be 3. Press on the impeller with drift SVO 2266 so

damaged. The sealing ring should always be that it comes flush with or down to O.4 mm

replaced by a new one.

5. When separating the sfaft and impeller, the

sealing ring is pressed down and press washer

SVO 2429 slid in under the impeller. The shaft

is then pressed out with drift SVO 2266. _

ASSEMBLING

' Before assembling, check carefully that the parts

i, are in good condition. The sealinQ surface of the _

l_ impeller must be smooth and tree from scratches.

_ The bearing should rotate easily without binding

'l but must not be loose. Replace damaged parts

with new ones. The sealing ring must alw8ys be

replaced with a new one.

1. Press down the shaft and bearing in the

,_ housing with drift SVO 2463 in a similar manner

to that shown in Fig. 86 s_ that the locking

wire can be inserted into its slot. Fit the

Iocking wire.

_ 2. Fit the deflector ring as shown in Fig 87. Fit VjOil_ViOi

i the Seating ring with drift S.VO 243O as shown Fig. g_. po_ition o_ dg_lg_tor _ing

,, _ 2-36

|