|

|

|

Begin OCR Text:

P

Anti-_ree_e _luid

During the winter, ethylene glycol with anti-cor-

rosion agents shouId be added to the cooling

water in order to prevent freezing. For necessary

quantities, see the specifications.

Methylated spirit should not be used since its

boiling point is too low. It is also unsatisfactoy

from a corrosion point of view.

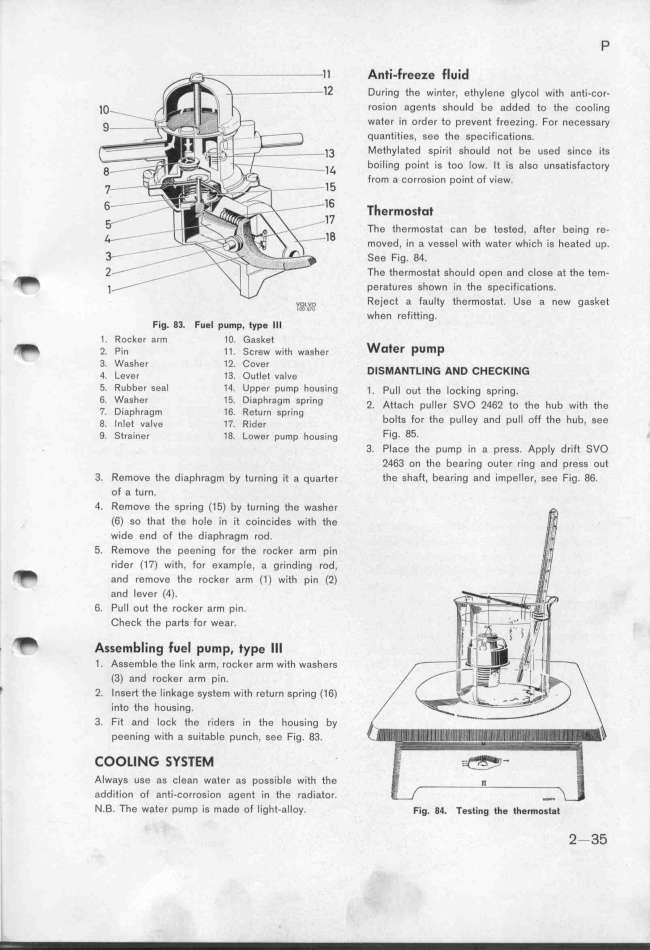

7hermostot

The thermostat can be tested, after being re-

moved, in a vessel with water which is heated up.

See Fig. 84.

_ The thermostat should open and close at the tem-

peratures shown in the specific Btions.

yg_,v,o, Reject a faUlty thermostat_ USe a new gasket

when refitting.

Fig. 83. Fuel pump, type Ill

1 . Rocker arm 1 O. Gasket w

_ 2. pin 1 1 . screw w_th washer otef pUmp

3. Washer 12. Cover D___A______ A_D _He_K___

4. Lever 13. OutIet valve

5. Rubber seal 14. Upper pump housing 1 . pu__ oui ihg _ošk_ing gp,_,ng.

6. Washer 15. Diaphragm spring _ Aiiašh pu__e, Svo 2462 io ihe hub w,_ih ihe

7. Diaphragm 16. Return spring ' b ii i ih ii d __ Fi h h b

g. _n_et va_ve 1_. R_,de, O S Or e pU ey an pU O t e U , See

9. Strainer t8. Lowgr pump hou6ing Fig_ 85_

3. Place the pump in a press. Apply drift SVO

2463 on the bearing outer ring and press out

3. Remove the diaphragm by turning it a Quarter the shaft, bearing and impeller, see Fig. 86.

of a turn.

4. Remove the spring (15) by turning the washer

(6) so that the hole in it coincides with the

wide end of the diaphragm rod.

5. Remove the peening for the rocker arm pin

_ rider (17) with, for example, a gr'inding rod,

and remove the rocker arm (1 ) witf pin (2)

and lever (4).

6. Pull out the rocker arm pin.

Check the parts for wear.

_ _ Assem_ling _Uel pump, type Ill

1 . Assemble the link arm, rocker arm with washers

(3) and rocker arm pin.

_ 2. Insert ihe linkage sysiem with return spring (16)

into the housing.

3. Fit and lock the riders in the housing by

peening with a suitable punch, see Fig. 83.

COOLING SYS_EM

Always use as clean water as possible with the

addition of anti-corrosion agent in the radiator.

N_B_ The water pump is made of light-alloy. Fig. $_. _esting __g t_g_o6tgt 2-35

|