|

|

|

Begin OCR Text:

j

P

_ _

Fig. 63. Me8suring the end tlo8t 'O'U'''O

_ check that the old one is not noficeably worn If '_W'V'

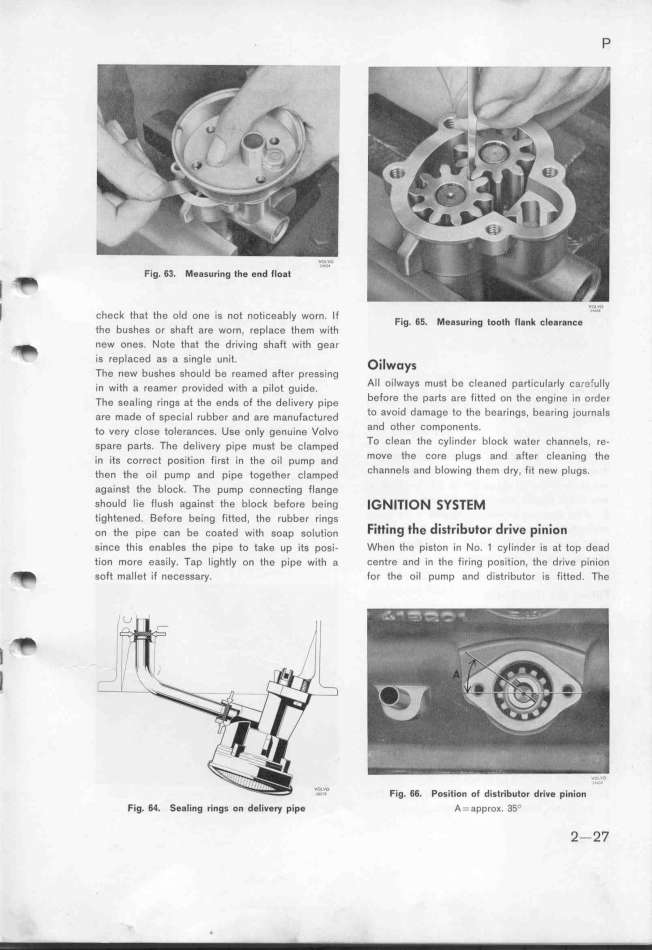

' Fl0. 65, Me8SUrlng tOoth tl8nk tle8r8nte

the bushes or shaft are worn, replace them with

_ new ones. Note that the driving shaft with gear

is replaced as a single unit. o___woy_

The new bushes should be reamed after pressing=

_,n w__ih a ,eame, p,ov_,ded w__ih a p_,_oi gu_,de. All oilways must be cleaned particularly care'_ully

The gea__,nQ ,_,,gg ai ihe e,d, o_ ehe dei_,,ey p_,pe before the parts are fitted on the engine in order

a,e made o_ gpec_,a_ ,ubbe, a,d a,e ma,,face,,ed to avoid dam8ge to the bearings, bearing journals

io ve,y šioge io_e,a,šeg. uge on_y genu_,ne vo_vo and other Components.

gpa,e pa,ig. The de__,vey p_,pe mugi be š_amped To Clean the cylinder block water channels. re-

_,n ,_ig šo,,eci pog__e__o, __,,gi _,, ihe o___ pump a,d moVe the core plugs and after cleaning the

ehen ihe o_,_ pump a,d p_,pe iogeihe, c_amped ChanneIS and blowing them dfy, fit new pIUgS.

against the block. The pump connecting flange

sfouId lie flush against the block before being ______O_ _y__E_

tightened. Before being fitted, the rubber rings _ d b d

on ihe p_pe can be coaeed wieh goap goiui,o, Fitting t e istri utor rive pinion

since this en8bles the pipe to take up its posi- When the piston in No. 1 cylinder is at top dead

tion more easily. Tap lightly on the pipe with a centre and in the firing position, tfe drive pinion

_ soft mallet if necessary. for the oil pump and distributor is fitted. The

_ '

__ Fig. 66. Position ot distributor drive pinion 'O'''''

Fig. 64. Sealing rings on delivery pipe A=appro_. 35'' 2-27

|