|

|

|

Begin OCR Text:

_

P

directions. See the Specifications for the dimen- -

sions concerned.

Re-boring the _yIinders

The cylinders are re-bored in a special mašhine,

after which they are honed in order fo obtain a

good surface finish. The complete cylinder block

should be washed in a degreasing tank before

being assembled in order to remove all grinding

residue and impurities.

See the Specifications for the dimensions concer-

ned, See also the teKt under the heading ''Fit of

pistons in cylinders''. . _- ' _,,_,o

' _ Fig. 46. Mgas_ring thg pisto_ ''

PISTONS, PlSTON RINGS AND

GUDGEON PINS

' 2. Measure the ring gap with a feeIer g8uge as

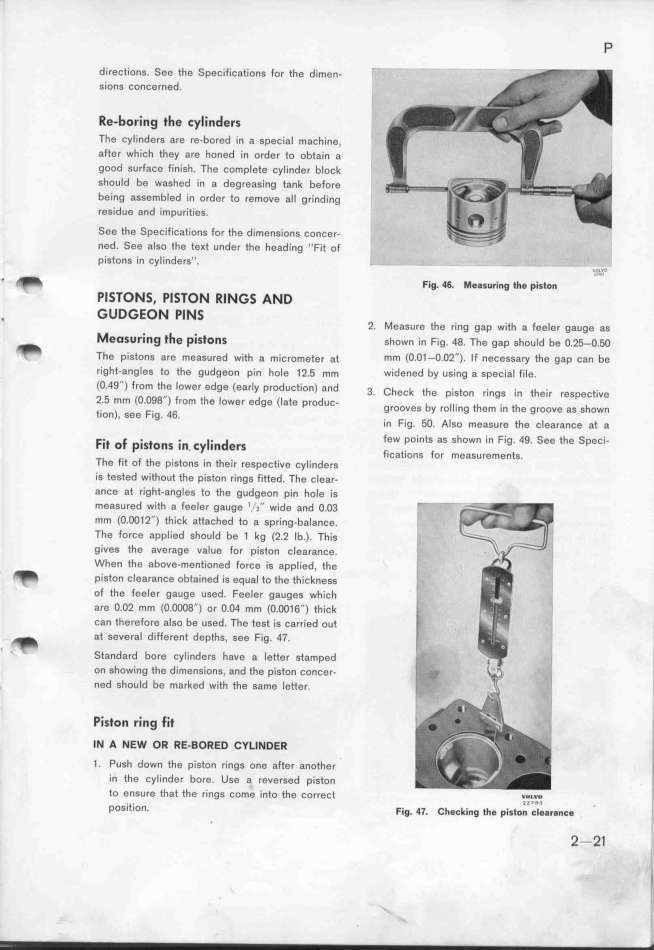

_ Meosvring the pistons shown in Fig. 48. The gap shou_d be o.2s-o.5o

The pistons are me8sured with a micrometer at mm (O_O1-O_O2''). If necessay the gap can be

right-angles to the gudgeon pin hole 12.5 mm widened by using a special file.

(O_49'') from the lower edge (early production) and 3 _h k _h _ t _ _ _h _ t_

. eC e pIS On ringS In e_r reSpeC ive

2_5 mm (O.O98'') from the lower edge (late produc- b __ h . h h

grooves y ro ing t em in t e groove as s own

tion), see Fig. 46. in Fig. 5O. Also measure tfe clearance at a

F_t _ _ t _ I_ d few pOints as shown in Fig. 49. See the Speci_

l O pIS onS In _y in ers

' fications for measurements.

The fit of the pistons in their respecfive cylinders

is tested w_ithout the piston rings fitted. The clear-

anCe at right-angles to the gudgeon pin hole is

measured with a feeler gauge ','_'' wide and O.O3

mm (O,OO12'') thick attached to a spring-balance.

The force applied should be 1 kg (2.2 Ib.). This

gives the average value for piston clearance.

_ When the above-mentioned force is applied. the

P_Ston ClearanC0 obtained is equal to the thickness

of the feeler gauge used. FeeIer gauges which

are O.O2 mm (O.OOO8'') or O.O4 mm (O.OO16'') thick

can therefore also be used. The test is carried out

_ at several different depths, see Fig. 47.

' ' Standard bore cylinders have a letter stamped _

on showing the dimensions, and the piston concer- _

, ned should be marked with the same letter.

Piston ring _it

l_ A _EW OR RE-BOffED _yLl_DER _

1. Push down the piston rings one after another _

in the cylinder bore. Use a reversed piston

to ensure that the rings come into the correct w,,_,v,o, ','

pOSitiOn. . Fig. 4_. __ešking __g pi__on š_gg_gnšg

2-21 _

|