|

|

|

Begin OCR Text:

__ _____ _ ____ _ w

_ _

g___

_ _

_ _

P

Il_

_

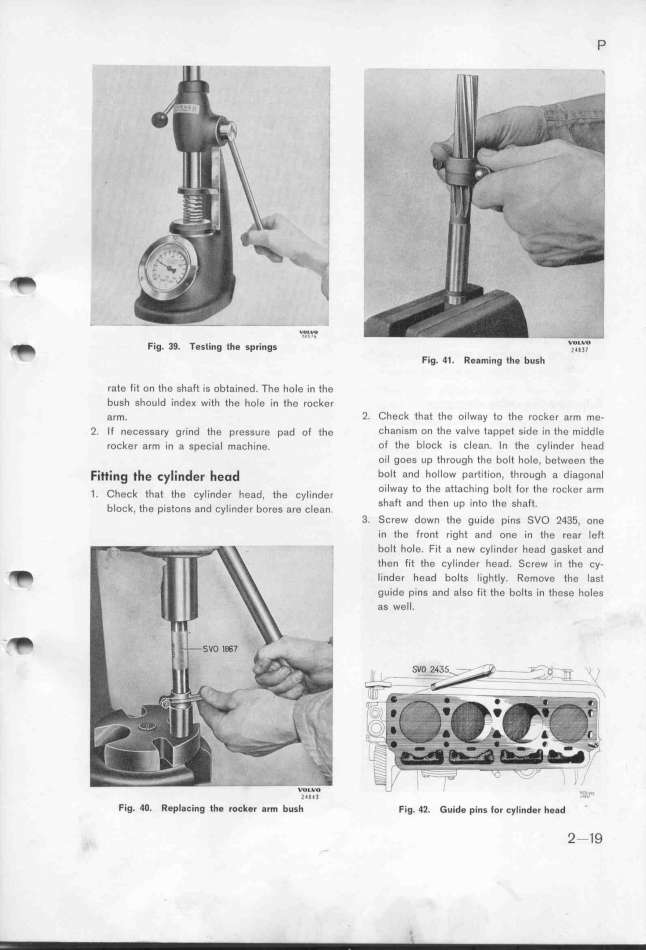

_ Fig. 39. Testing the spri_gs ''''W'' __O_'____O

_ Fig. 41. Reaming the bush

rate fit on the shaft is obtained. The hole in the

bush should inde_ with the hole in the rocker

arm. 2. Check that the oilway to the rocker arm me-

2. If necessary grind the pressure pad of the chanism on the valve tappet side in tfe middle

rocker arm in a special machine. of the block is clean. ln fhe cylinder head

oil goes up through the bolt hole, between the

Fi_i_g __e _y_i_de_ _eod boIt and hollow partition, through a diagonal

_ _h _ th t th _. d h d h _. d o_lway to the attaching boIt for the rocl(er arm

_ eC a e Cy In er ea , t e Cy In er h _ d h h

bi _ th _ t d i_ d b _ S a t an t en Up infO t e Shaft.

OC , e pIS OnS an Cy In el OleS are C ean 3. Screw down the guide píns SVO 2435, one

in the front right and one in the rear left

_ boIt hoIe. Fit a new cylinder head gasket and

'i then fit the cylinder head. Screw in the cy-

_ lind8r head bolts lightly. Remove the last

guide pins and also fit the bolts in these holes

as well.

_ WZlL_W4I 'U__,_W_

Fig_ 4O_ Repl8_ing the roeker arm bush Fig. 42. Guide pins _or _y_i_d$r hggd

2__9

|