|

|

|

Begin OCR Text:

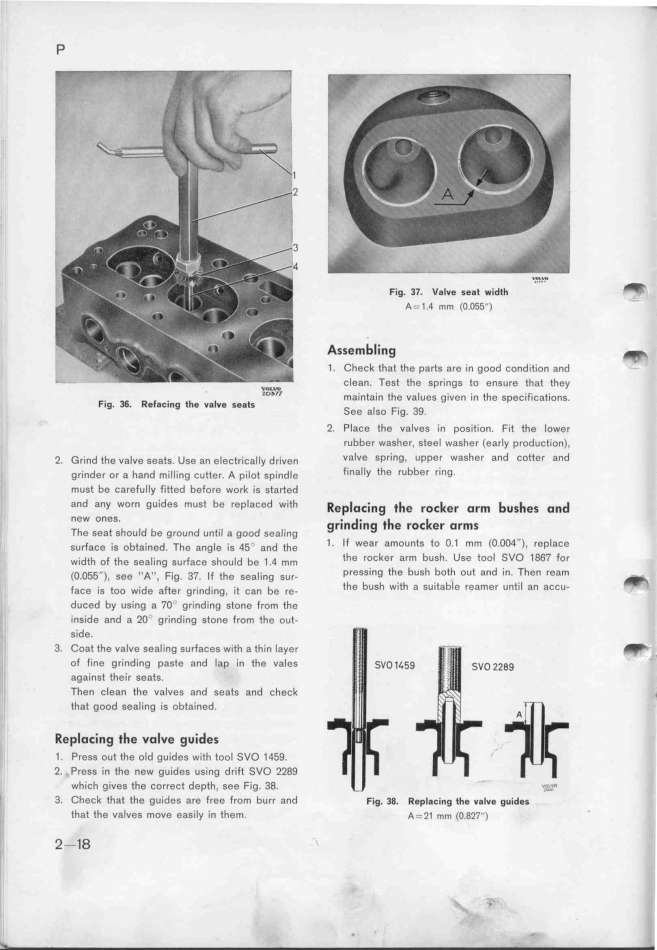

P Fig, 3_. v8Ive se8t wid__ __ _

A=1.4 mm (O.O55'') -

Assemb_ ling _

1_ Check that the parts are in good condition and

w_ Clean. Test the springs to ensure that they

F_,g 36 ff$_,,_,,g t_, ,,_,e ,e,t, 'O''' maintain the values given in the specifications.

' ' See also F_ig. 39.

2_ Place the valves in position. Fit tfe lower

rubber washer, steel washer (early production),

2. Grind the valve seats. u,e a, electrjša__y driven Valve spring_ upper washer and cotter and

grinder or a hand milling cutter. A pi_ot ,pind_e finally the rubber ring.

must be carefuIIy fitted before work is sta_ed

and any worn guides must be rep_aced with RepIo__ing i_e fo__ef ofm bushes ond

neW OneS. _ d_ i_ _

_he se,t ,fou_d be ground ,nt,__ a good sea_j.,g gfln Ing e fO_ ef OfmS

gurfacg is obtajned. The a,g_e i, 4_ _ and tfe 1_ If wear amounts to O.1 mm (O.OO4''), replace

widtf of tfe sea_ing su_ace gfould be _.4 mm the roCker arm bush. Use tool SVO 1g67 for

(o.o55''), gee ,,A,_, Fig. 37. _F the seal_i,g ,u,- pressing the bush both out and in. Then ream _

face is too wide after grj,di,g, jt can be ,e. the bUsh with a suitable reamer untjl an accu_

duced by using a 7O' grinding stone from the

inside and a 2O grinding stone from the out-

side.

3_ Coat the valve sealing surfaces with athjn layer

_

of fine grinding paste and lap in the vales __5g

o__gg '

against their seats.

Then clean the valves and seats and šheck ,

that good sealing is obtained.

RepIo_ing the voIve guides

1. Press out the old guides with tool SVO 145g.

2. . Press in the new guides using dri_ SVO 22gg

whÝch gives the correct depth, see Fjg. 3g. __,,_

! 3, Check that the guides are free from burr and F_,g. 3g. ffgp_,,_,,g t_e ,,_,e g,_,d,,

that the valves move easily in them. A___1 mm (o.g____)

_

' 2-18

|