|

|

|

Begin OCR Text:

P

Remove the flywheel housing tog$ther with the

ge8rbo_ and then remove the clutch and

flywhe$l.

3. Remove the rear flange, taking c8re not to

damaQe the contact surfaces, the dyn8mo.

wat$r pump and distributor, rocker caGíng, roc-

ker arme. cylinder head and oil filter.

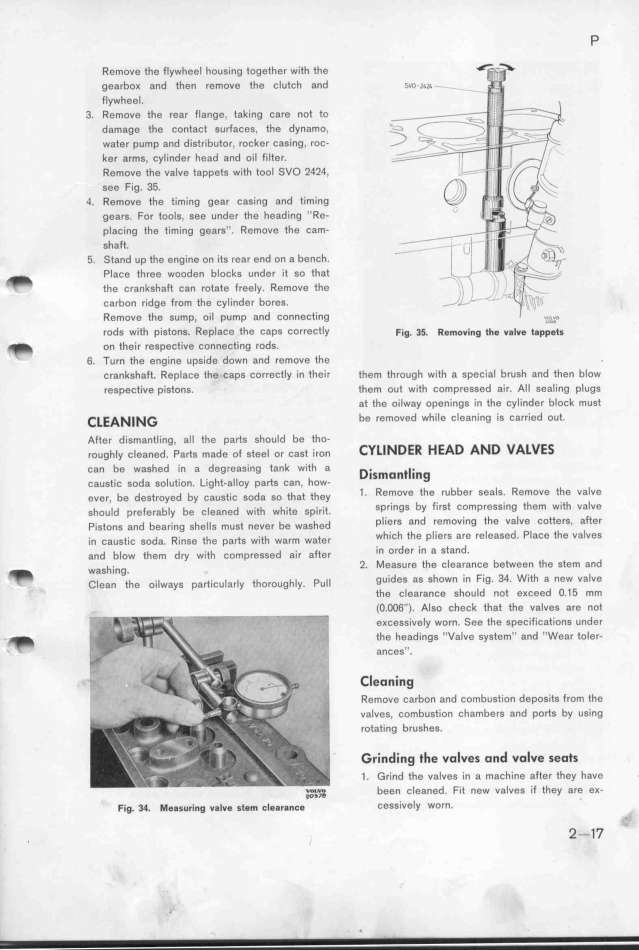

Remove the valve tappefs with tool SVO 2424,

see Fig. 35.

4. Remove the timing gear casing and timing

gears. For tools, see under the heading ''Re_

placing the tim'ing gears''. Remove the cam-

shaft.

5. Stand up th$ engine on ite rear end on a bench.

_ Place three wood8n blocks under it so that

the crankshaft can rotate freely. Remove the

carbon ridg$ from the cylinder bores.

Remove the sump, oil pump and connecting ..,.,

rods with pistons_ Replace tfe caps correctly Fig. 3_. ff$movi_g thg v8_vg tgppg_g

_ on their respective connecting rods.

_ 6. Turn the engine upside down and remove the

crankshaft. Replace the caps correctly in their them through with a special brush and then blow

respective pistons. them out with compressed air. All sealing plugs

at the oilway op$nings in the cylinder block must

tlEAN_NG be removed while cleaning is carried out.

After dismantling, all the parts should be tho- ty EAD AND vA vE_

,ough_y ç_ea,ed. pa_g made o_ g_$e_ o, çag_ i,on LINDER H L

c8n be waShed in a degreasing tank With a D_is_ont__ing

caustíc soda solution. L_ight-alloy parts can, how-

evg,, be dgg_,oyed by çaugt_,ç goda go that _hey 1_ RemoVe the rUbb0l SeaIS_ Remove the v8lVe

ghou_d p,e_e,ab_y be ,_ea,ed w_ith wh_ite gp_,,_,t. springS by firSt CompreSSing them With Valve

p_,gto,g a,d bea,,_,Q ghe__g mugt ,eve, be waghed pliers and removing the valve CottefS, after

_in çau6t__ç goda. R_,,ge the pa,tg w_,th wa,m wgte, whicf the pliers are releaSed. PlaCe the valveS

and b_ow them dy w_ith çomp,egggd a_i, a_te, in order in a stand_

_ wggh_ing. 2. Measure the Clearance between the Stem and

__e,, th, ,_,_w,y, p,,t;,,_a,_y th,,,,gh_y. p,__ 9UideS aS ShoWn in Fi9_ 34_ Wíth a n$W VaIV0

tfe clear8nce should not e_ceed O.15 mm

(O.OO6''). Also cfeck that the valves are not

e_cessively worn. See the specifications under

_ th$ headings ''Valve system'' and ''Wear toler_

_ anCeSI'.

tleoning

Remove carbon and combustion deposits from the

valves, combustion chambers and ports by using

rotating brushes.

Grinding the volves ond volve seots

1. Grind the valves in a machine after they have

__ _ been cleaned. Fit new valves if they are e_-

Fig. 34. _ggg__i_g vg_ve gtgm __gg_g__$ CessiveIy WOrn_ ,

. 2-17 '-

|